Welcome to the innovative and precise world of 3D laser cutting! This comprehensive guide will walk you through all you need to know about 3D laser cutting in Melbourne, whether you’re an engineering whiz, a manufacturing enthusiast, or you’re just interested in cutting edge technology. Prepare to discover the countless advantages and opportunities that this cutting-edge method has to offer. Now let’s get started!

Selecting the Appropriate 3D Laser Cutting Service Supplier

Selecting the best 3d laser cutting Melbourne service provider requires careful consideration of elements including experience, knowledge, technological prowess, and client testimonials. You can guarantee excellent project outcomes by choosing a trustworthy business that satisfies your unique needs. Be sure to compare several services and conduct in-depth research before deciding. You may benefit from 3D laser cutting’s many advantages in a variety of industries if you have the proper partner by your side.

Perks of using a 3D laser to cut

With so many advantages, 3D laser cutting is the best option for precise cutting requirements. The great degree of accuracy it offers, which guarantees that complex ideas be completed flawlessly, is one of its main advantages. Additionally, this technique minimises material waste by enabling the consistent and effective cutting of complex shapes.

The adaptability of 3D laser cutting to a variety of materials, including metals, polymers, wood, and more, is another important advantage. Because of this, it is an adaptable option for a variety of businesses trying to accomplish accurate cuts on various materials. Furthermore, the fact that laser cutting is non-contact helps shield the material being worked on from contamination or damage.

Moreover, 3D laser cutting reduces the need to switch out tools mid-project, resulting in quicker turnaround times and higher production. Its versatility in handling both easy and complex cuts makes it the perfect option for projects demanding a great degree of customisation and detail.

How Do You Perform 3D Laser Cutting?

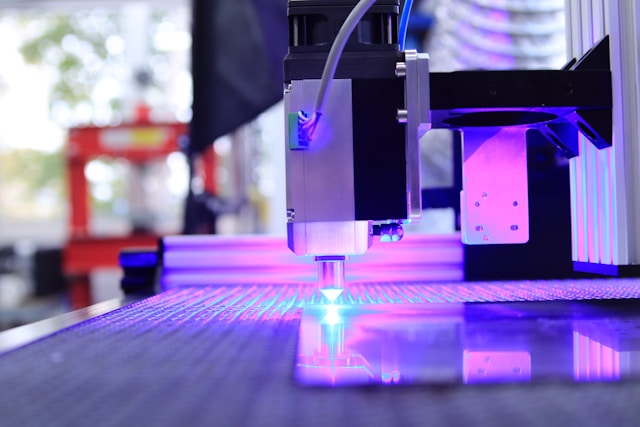

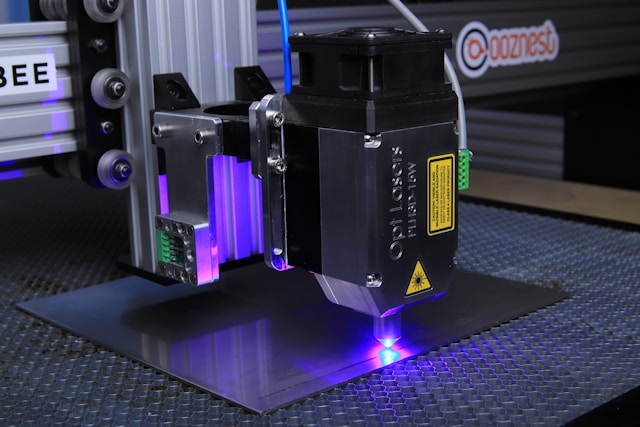

Using state-of-the-art technology, 3D laser cutting uses laser power to accurately and precisely cut through a variety of materials. First, a digital three-dimensional model of the design that needs to be cut is created. This model directs the intense laser beam along the predetermined path, melting, burning, or vaporising the material.

Sophisticated software controls the laser beam that is released from a nozzle, making it easy to create elaborate and sophisticated shapes. Depending on the material being cut—metal, plastic, wood, or even fabric—the laser’s intensity can be changed.

With no physical contact, the laser’s high heat produced when it slices through the material produces crisp edges. In addition to minimising material waste, this non-contact technology dramatically shortens manufacturing times.

All things considered, 3D laser cutting is transforming manufacturing procedures in a variety of industries by providing unparalleled accuracy and productivity in the effortless creation of complex designs.

Utilising 3D Laser Cutting in Various Sectors

3D laser cutting technology is very versatile and important across a wide range of sectors. Precision is essential in the automobile industry when cutting intricate forms and designs for vehicle components. 3D laser cutting helps the aerospace sector create lightweight, finely detailed parts that ensure maximum performance and fuel efficiency.

3D laser cutting is used in the medical profession to make precise implants and surgical equipment that are suited to the individual anatomy of each patient. This technique is used by the electronics industry to cut circuit boards and microelectronic components with extreme precision, improving production processes’ accuracy and efficiency.

In addition, the architectural and design industries use 3D laser cutting to create custom furniture items, interior décor elements, and building facades with elaborate patterns and detailed designs. The uses of 3D laser cutting in a variety of industries, from the creation of signage to fashion items, are only growing as technology progresses.